Management

the numbers explained

What is loading accuracy?

Loading accuracy is a comparison between the requested and the loaded amounts of feed. In other words, how well is the feed grabber capable of loading the MFR precisely? This precision is crucial for maintaining a constant ration and promoting the health of your livestock. To know and track what you feed your animals, it is important that what you really feed is as close as possible to what you want to feed. This can also be referred to as the calculated ration and the fed ration. The calculated ration being the ration that you calculated, so what you want to feed. And the fed ration being the ration that you actually feed.

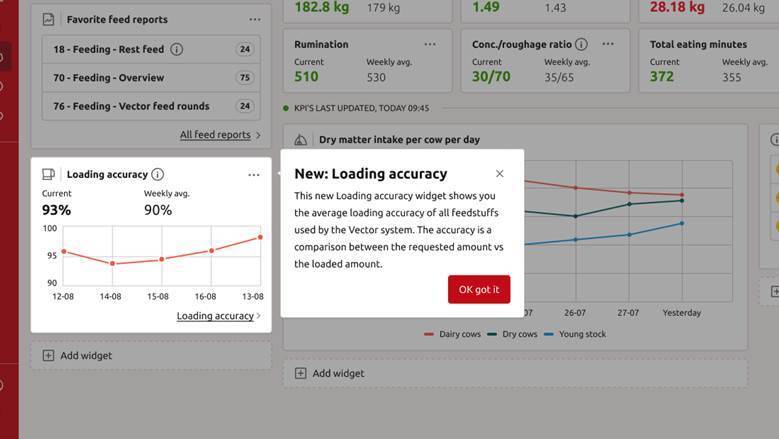

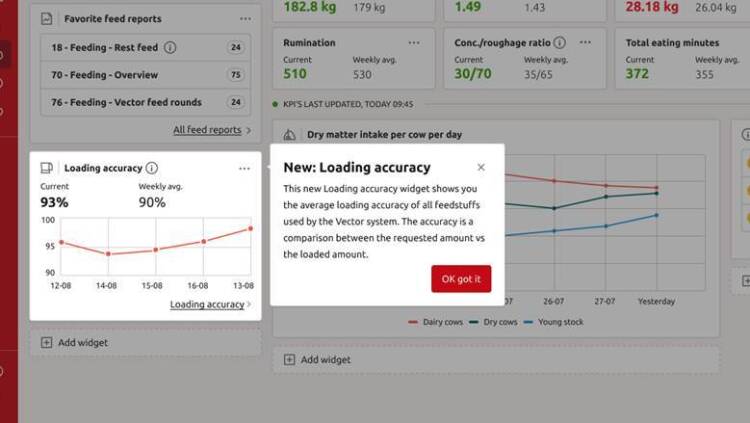

You can find the loading accuracy: in Horizon within the new widget, both the general average and the average per load will be visible.

What does the software think?

The feed grabber accepts a difference of 10%. So, if you need a total of 10kg of straw, the feed grabber will accept grabs between 9-11kg. However, it is impossible for the grabber to detect amounts smaller than 2kg. In the end, for a request of 10kg, the feed grabber will accept grabs between 8 and 12kg.

To avoid endless retrying, exceeding the requested ration weight and prevent a lot of grabs for a last small amount, there is a maximum and minimum deviation range: 10% of requested weight with a max of 20kg. The lowest amount the MFR will request depends on the total amount of a feedstuff in the load.

Bear in mind that to execute an accurate weight estimation, the distance between the top of a feed block and the feed grabber, should be at least is 1meter.

What influences loading accuracy?

First, the loading accuracy is influenced by the type of feed you are loading. Long fluffy materials have the tendency to be less accurate. So, know that straw or hay will never be as accurate as corn silage. If a high loading accuracy is very important to a farmer, make sure to manage his expectations according to the feed types he is feeding.

It is important to indicate correctly, in Horizon, wat feed type is in which storage place. Also make sure that the correct settings for each feed type are chosen: is it a block, a round bale or a loose material? Wat is the particle length? The feed grabber is constantly learning how to approach a certain feed type. It will show strange behavior if it thinks it is grabbing a certain feed type, but really, it is something else.

The loading accuracy is directly influenced by the number of retries set. The more retries you set, the more chances you give the feed grabber to be accurate and correct its mistakes. Be careful because this influences the capacity of the feed grabber. So, retries should be a balance between capacity and accuracy. If you set 0 retries, the feed grabber will only grab once, and that is it. If it then is way off the requested weight, then that is too bad. So, our advice is to, at least, set 1 retry, even if you feel like the system does not have the capacity.

The loading accuracy can also be influenced by the outside temperature and how busy the system is. When it is cold outside and/or when the feed grabber is not doing anything for a longer period of time, the oil in the feed grabber will be cold and thicker, making the weight estimation less accurate. The resistance on the belts will be higher, making the feed grabber think it has more weight than it has. In the case where it is cold and/or the system is not busy, it is recommended to start loading with a feed type that requires a lot of bites to warm up the oil. This could mean that you deviate from the rule of thumbs: long before short and dry before wet. So always consider if this is possible!

The loading order can also have an influence on loading accuracy. Each time, before the feed grabber is sent out to grab the next grab, the system will check how much is already in the bin. If there is already more than 110% of the requested weight, the product will not be loaded anymore. So, pay attention to the feedstuff that is going in last. It could be that the overshooting of other feedstuffs results in the last feedstuff not being dosed completely or at all.

The loading accuracy is not only influenced by settings like the grab depth and cleaning level. But also, by the silage management, feed density, block placement and kitchen management. If you are struggling with the accuracy level, and you cannot find a reason in the items mentioned above, consider taking a broader view. Also, make sure to use a correct block cuter to cut blocks that are easily approachable for the feed grabber.

Make sure that the feed grabber is properly calibrated: the positioning of the jaws, the belts (properly wrapped, same tension on all belts), the position of the laser (center of feed block), and lot of empty grabs. If you feel like the calibration is off, have it checked by a technician.

Best practices

Manage expectation based on the type of feedstuffs.

Make sure that the correct feedstuff is in the right storage place like it is indicated in Horizon.

Use the correct feed grabber setting for each feedstuff.

Play around with the retries. Allow more retries when feed stuffs have the tendency to be less accurate.

The distance between the top of a block and the feed grabber should never be less

than 1 meter.Take the time needed to warm up the oil in consideration if needed.

Know that the loading order can have an influence on your accuracy.

Have a good kitchen management: block placement, clean up feed scraps, …

Contact technician is calibration is off.

Never change more than 1 or 2 settings at the same time if you want to be able to know which change had an influence (positive or negative).

Always be on farm when making changes to the settings and check what the system is doing.

October 2024

Achieving a high loading accuracy with the Vector system can be challenging. Luckily, there are many things that you can do to achieve this > 95% accuracy! Do you want to know what can go better? Keep on reading!

accuracy

What influences loading accuracy?

First, the loading accuracy is influenced by the type of feed you are loading. Long fluffy materials have the tendency to be less accurate. So, know that straw or hay will never be as accurate as corn silage. If a high loading accuracy is very important to a farmer, make sure to manage his expectations according to the feed types he is feeding.

It is important to indicate correctly, in Horizon, wat feed type is in which storage place. Also make sure that the correct settings for each feed type are chosen: is it a block, a round bale or a loose material? Wat is the particle length? The feed grabber is constantly learning how to approach a certain feed type. It will show strange behavior if it thinks it is grabbing a certain feed type, but really, it is something else.

The loading accuracy is directly influenced by the number of retries set. The more retries you set, the more chances you give the feed grabber to be accurate and correct its mistakes. Be careful because this influences the capacity of the feed grabber. So, retries should be a balance between capacity and accuracy. If you set 0 retries, the feed grabber will only grab once, and that is it. If it then is way off the requested weight, then that is too bad. So, our advice is to, at least, set 1 retry, even if you feel like the system does not have the capacity.

The loading accuracy can also be influenced by the outside temperature and how busy the system is. When it is cold outside and/or when the feed grabber is not doing anything for a longer period of time, the oil in the feed grabber will be cold and thicker, making the weight estimation less accurate. The resistance on the belts will be higher, making the feed grabber think it has more weight than it has. In the case where it is cold and/or the system is not busy, it is recommended to start loading with a feed type that requires a lot of bites to warm up the oil. This could mean that you deviate from the rule of thumbs: long before short and dry before wet. So always consider if this is possible!

The loading order can also have an influence on loading accuracy. Each time, before the feed grabber is sent out to grab the next grab, the system will check how much is already in the bin. If there is already more than 110% of the requested weight, the product will not be loaded anymore. So, pay attention to the feedstuff that is going in last. It could be that the overshooting of other feedstuffs results in the last feedstuff not being dosed completely or at all.

The loading accuracy is not only influenced by settings like the grab depth and cleaning level. But also, by the silage management, feed density, block placement and kitchen management. If you are struggling with the accuracy level, and you cannot find a reason in the items mentioned above, consider taking a broader view. Also, make sure to use a correct block cuter to cut blocks that are easily approachable for the feed grabber.

Make sure that the feed grabber is properly calibrated: the positioning of the jaws, the belts (properly wrapped, same tension on all belts), the position of the laser (center of feed block), and lot of empty grabs. If you feel like the calibration is off, have it checked by a technician.

Best practices

Manage expectation based on the type of feedstuffs.

Make sure that the correct feedstuff is in the right storage place like it is indicated in Horizon.

Use the correct feed grabber setting for each feedstuff.

Play around with the retries. Allow more retries when feed stuffs have the tendency to be less accurate.

The distance between the top of a block and the feed grabber should never be less than 1 meter.

Take the time needed to warm up the oil in consideration if needed.

Know that the loading order can have an influence on your accuracy.

Have a good kitchen management: block placement, clean up feed scraps, …

Contact technician is calibration is off.

Never change more than 1 or 2 settings at the same time if you want to be able to know which change had an influence (positive or negative).

Always be on farm when making changes to the settings and check what the system is doing.

the numbers explained

Management

Achieving a high loading accuracy with the Vector system can be challenging. Luckily, there are many things that you can do to achieve this > 95% accuracy! Do you want to know what can go better? Keep on reading!

accuracy

October 2024

What is loading accuracy?

Loading accuracy is a comparison between the requested and the loaded amounts of feed. In other words, how well is the feed grabber capable of loading the MFR precisely? This precision is crucial for maintaining a constant ration and promoting the health of your livestock. To know and track what you feed your animals, it is important that what you really feed is as close as possible to what you want to feed. This can also be referred to as the calculated ration and the fed ration. The calculated ration being the ration that you calculated, so what you want to feed. And the fed ration being the ration that you actually feed.

You can find the loading accuracy: in Horizon within the new widget, both the general average and the average per load will be visible.

What does the software think?

The feed grabber accepts a difference of 10%. So, if you need a total of 10kg of straw, the feed grabber will accept grabs between 9-11kg. However, it is impossible for the grabber to detect amounts smaller than 2kg. In the end, for a request of 10kg, the feed grabber will accept grabs between 8 and 12kg.

To avoid endless retrying, exceeding the requested ration weight and prevent a lot of grabs for a last small amount, there is a maximum and minimum deviation range: 10% of requested weight with a max of 20kg. The lowest amount the MFR will request depends on the total amount of a feedstuff in the load.

Bear in mind that to execute an accurate weight estimation, the distance between the top of a feed block and the feed grabber, should be at least is 1meter.