2022 electricity supply at Lely Campus, Maassluis, NL

100%

Green electricity

87%

European wind energy

13%

Generated by our own 3,545 solar panels

+

Health & Safety

+

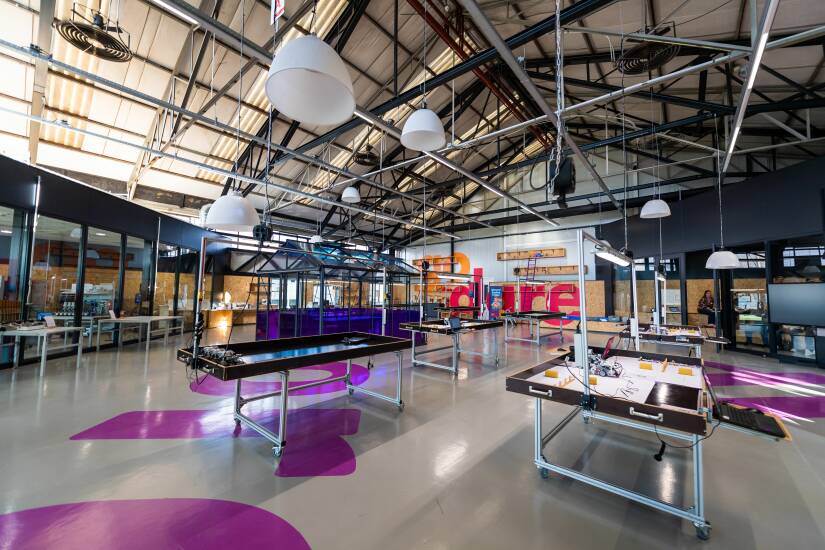

GoDare

+

Fit@Lely

An important way to enhance the sustainability of our operational activities is to reduce the amount of non-reusable packaging.

waste streams at

the Lely Campus

HVO stands for “Hydrotreated Vegetable Oil” and is the most sustainable diesel fuel at the moment.

Refurbishment is the process of repairing or modifying an object that is waste or a product to restore its performance or functionality within the intended use.

E-link

In 2023, we will reach out to our internal and external stakeholders by performing a double materiality assessment. This assessment will give us more insight into what sustainability topics we should prioritise in our reporting.

We will include more scope 3 categories in our emission calculations to gain fuller insight into our GHG emissions.

In addition, we will continue to implement our Circularity strategy and roadmap and perform baseline measurements in 2023.

Lely is a family business rooted in family values. We take care of our 2,100 employees, our customers around the globe and the communities where we operate. People are at the heart of our business, and we see it as our duty to contribute to their well-being. As an employer, we act on our mission and vision to create a strong sense of purpose. We provide employees with opportunities for personal and professional development. And by supporting initiatives designed to empower the next generation of innovators, we not only ‘pay it forward’ based on our company's success, but also share our passion for farming – for enjoyable, profitable and sustainable farming, now and in the future.

Circularity

Lely strives for circular dairy farming. This ambition is also in place for our own products and services.

Within “Bright Business”, circularity forms one of the three focus areas of the Lely Sustainability programme. To structurally embed circularity within Lely’s design, innovation and practice, we joined forces with an external partner in 2022 to set up our circularity strategy and roadmap for 2030. The strategy helps to define circularity for Lely and the roadmap breaks it down into quantifiable milestones and targets with associated KPIs and activities.

Our decarbonisation path

In 2021 Lely started measuring the scope 1 and 2 of our CO2 footprint, and scope 3 category business travel was also included.

In April 2022 we formulated our Lely CO2 ambition: Lely commits to becoming CO2-neutral in our own operations by 2030. In line with that we launched an action plan aimed at achieving this ambition:

Switch to green electricity in all our facilities by 2027

Complete the gas phase-out in our facilities by 2030

Have a zero-fossil fleet in 2030

Fly 50% less (compared to 2019)

Offset all remaining CO2 emissions to be ‘net zero’ (starting from 2023)

To achieve our ambition and reduce emissions, we initiated multiple projects. These are detailed below.

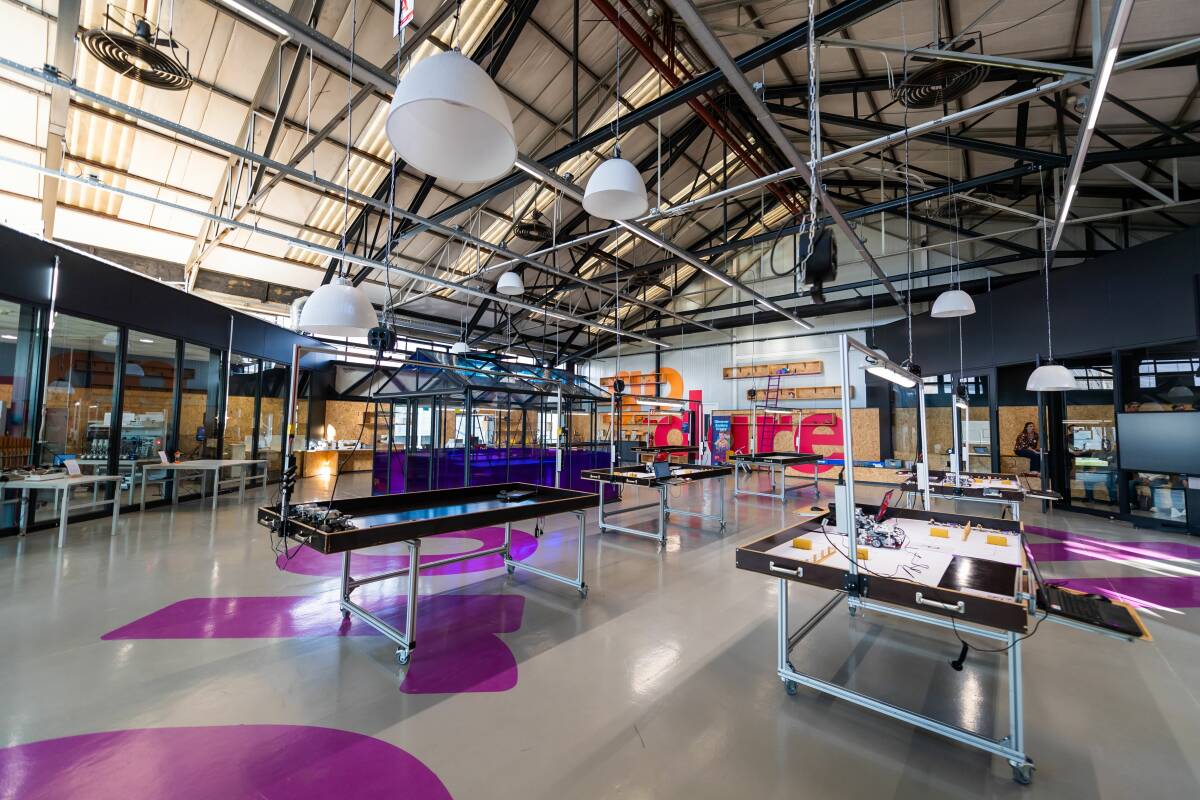

Energy management at Lely Campus Maassluis, NL

In 2022 phase 2 of our Lely Campus was opened to support the growth of our business. We also optimised the climate system at our phase 1 facilities, resulting in a reduction of natural gas consumption.

Company cars

In our lease fleet we are focusing on the switch to a non-fossil fleet. At Lely Campus level, the share of electric vehicles is 14% in 2022. In 2022 we started developing a new lease policy which will further support this transition.

Business flights

With COVID restrictions being lifted we observed a change in behaviour with regard to business travel compared to the previous two years. We still see a reduction compared to pre-COVID years, but there is a need to create awareness and to make conscious choices. In 2023, we will update our travel policy and implement a new travel tool to support sustainable travel choices.

Sustainability programme

Our sustainability programme is built on two pillars:

- Bright Business is about how we act and work as a company. We recognise that achieving our mission starts with our own business activities and operations.

- Bright Farming is about having a positive impact on dairy farming. We aim to make positive contributions to the sector with our solutions and through our business activities.

Within these three pillars, we have identified three ambitions:

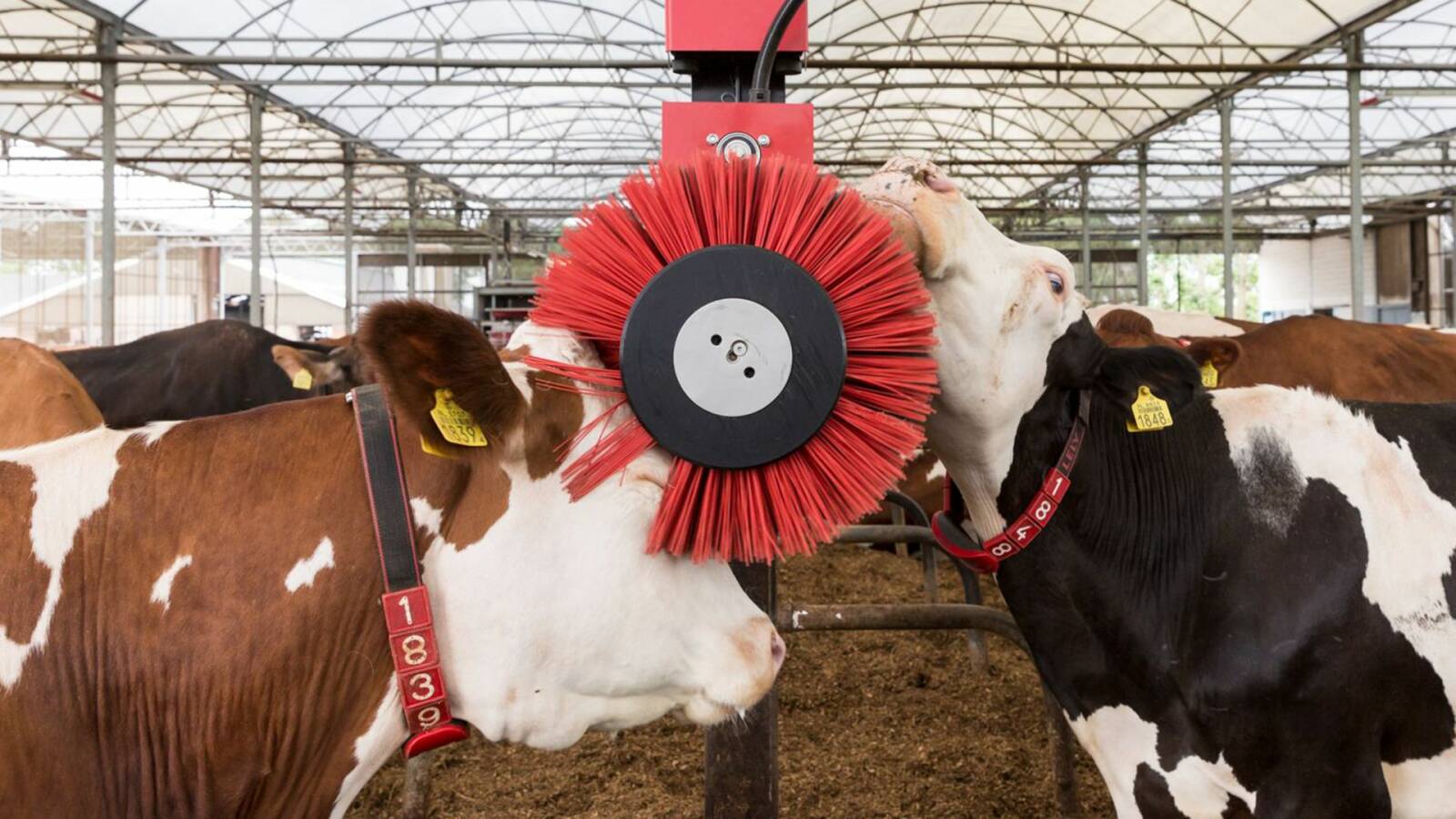

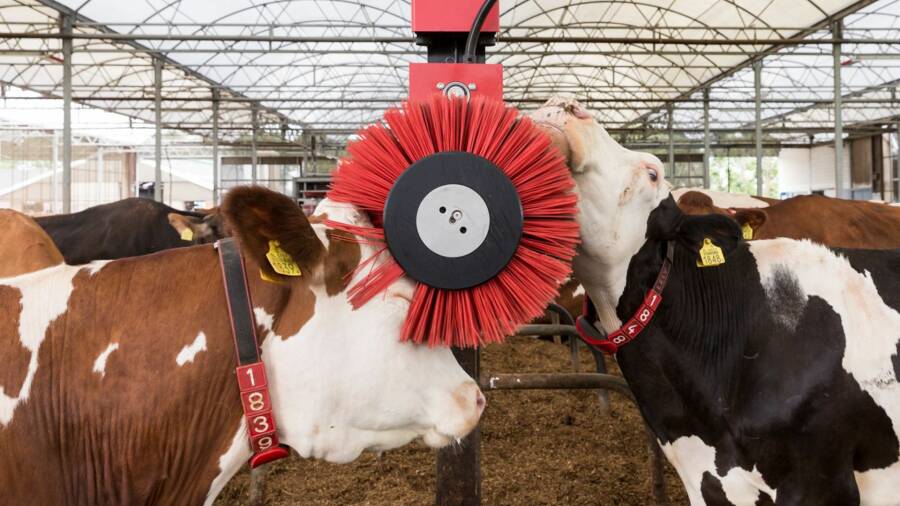

- For cow – to contribute to improving animal welfare on dairy farms.

- For people – to facilitate enhancing the well-being of people in every part of the dairy chain.

- For planet – to make it possible to reverse the environmental impact in every part of the dairy chain.

Sustainable, profitable

and enjoyable

To feed an estimated 10 billion people by 2050, global food production must be increased by 70%. Dairy farming plays a significant role in providing essential nutrition to this growing population. At the same time, the awareness of the impact of dairy farming is growing, both within the sector and among consumers, who want to be assured that their dairy products are produced with genuine care for cow, people and planet. In 2020, Lely began its sustainability journey aimed at improving animal welfare, reversing the dairy industry's environmental impact and supporting farmers. By taking responsibility for our own impact as well as the impact that our solutions have on the industry's impact, we can achieve our vision of a sustainable, profitable and enjoyable future in farming.

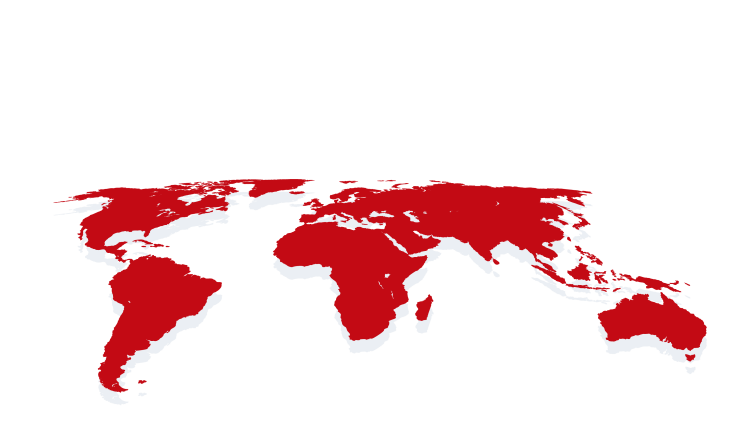

At Lely, we are on a journey to help farmers meet their needs and realise the potential of dairy in a sustainable, profitable and enjoyable way. This has been our driving force since 1948. We want to accelerate change and drive progress. We are farming innovators.

100%

Green electricity

87%

European wind energy

13%

Generated by our own 3,545 solar panels

2022 electricity supply at Lely Campus, Maassluis, NL

Lely is a family business rooted in family values. We take care of our 2,100 employees, our customers around the globe and the communities where we operate. People are at the heart of our business, and we see it as our duty to contribute to their well-being. As an employer, we act on our mission and vision to create a strong sense of purpose. We provide employees with opportunities for personal and professional development. And by supporting initiatives designed to empower the next generation of innovators, we not only ‘pay it forward’ based on our company's success, but also share our passion for farming – for enjoyable, profitable and sustainable farming, now and in the future.

+

Health & Safety

+

GoDare

+

Fit@Lely

An important way to enhance the sustainability of our operational activities is to reduce the amount of non-reusable packaging.

waste streams at

the Lely Campus

HVO stands for “Hydrotreated Vegetable Oil” and is the most sustainable diesel fuel at the moment.

Refurbishment is the process of repairing or modifying an object that is waste or a product to restore its performance or functionality within the intended use.

E-link

In 2023, we will reach out to our internal and external stakeholders by performing a double materiality assessment. This assessment will give us more insight into what sustainability topics we should prioritise in our reporting.

We will include more scope 3 categories in our emission calculations to gain fuller insight into our GHG emissions.

In addition, we will continue to implement our Circularity strategy and roadmap and perform baseline measurements in 2023.

Circularity

Lely strives for circular dairy farming. This ambition is also in place for our own products and services.

Within “Bright Business”, circularity forms one of the three focus areas of the Lely Sustainability programme. To structurally embed circularity within Lely’s design, innovation and practice, we joined forces with an external partner in 2022 to set up our circularity strategy and roadmap for 2030. The strategy helps to define circularity for Lely and the roadmap breaks it down into quantifiable milestones and targets with associated KPIs and activities.

Our decarbonisation path

In 2021 Lely started measuring the scope 1 and 2 of our CO2 footprint, and scope 3 category business travel was also included.

In April 2022 we formulated our Lely CO2 ambition: Lely commits to becoming CO2-neutral in our own operations by 2030. In line with that we launched an action plan aimed at achieving this ambition:

Switch to green electricity in all our facilities by 2027

Complete the gas phase-out in our facilities by 2030

Have a zero-fossil fleet in 2030

Fly 50% less (compared to 2019)

Offset all remaining CO2 emissions to be ‘net zero’ (starting from 2023)

To achieve our ambition and reduce emissions, we initiated multiple projects. These are detailed below.

Energy management at Lely Campus Maassluis, NL

In 2022 phase 2 of our Lely Campus was opened to support the growth of our business. We also optimised the climate system at our phase 1 facilities, resulting in a reduction of natural gas consumption.

Company cars

In our lease fleet we are focusing on the switch to a non-fossil fleet. At Lely Campus level, the share of electric vehicles is 14% in 2022. In 2022 we started developing a new lease policy which will further support this transition.

Business flights

With COVID restrictions being lifted we observed a change in behaviour with regard to business travel compared to the previous two years. We still see a reduction compared to pre-COVID years, but there is a need to create awareness and to make conscious choices. In 2023, we will update our travel policy and implement a new travel tool to support sustainable travel choices.

Sustainability programme

Our sustainability programme is built on two pillars:

- Bright Business is about how we act and work as a company. We recognise that achieving our mission starts with our own business activities and operations.

- Bright Farming is about having a positive impact on dairy farming. We aim to make positive contributions to the sector with our solutions and through our business activities.

Within these three pillars, we have identified three ambitions:

- For cow – to contribute to improving animal welfare on dairy farms.

- For people – to facilitate enhancing the well-being of people in every part of the dairy chain.

- For planet – to make it possible to reverse the environmental impact in every part of the dairy chain.

Sustainable, profitable

and enjoyable

To feed an estimated 10 billion people by 2050, global food production must be increased by 70%. Dairy farming plays a significant role in providing essential nutrition to this growing population. At the same time, the awareness of the impact of dairy farming is growing, both within the sector and among consumers, who want to be assured that their dairy products are produced with genuine care for cow, people and planet. In 2020, Lely began its sustainability journey aimed at improving animal welfare, reversing the dairy industry's environmental impact and supporting farmers. By taking responsibility for our own impact as well as the impact that our solutions have on the industry's impact, we can achieve our vision of a sustainable, profitable and enjoyable future in farming.

At Lely, we are on a journey to help farmers meet their needs and realise the potential of dairy in a sustainable, profitable and enjoyable way. This has been our driving force since 1948. We want to accelerate change and drive progress. We are farming innovators.