The coming year promises to be more challenging, due to some of the issues faced by farmers, such as low milk prices, high interest rates and political unrest. However, the long-term outlook for robotics and data management remains very bright.

Our focus for 2024 is the further development of competences in all regions, and the continuous improvement of our existing propositions to better serve our the needs of our customers. Alongside that, we will increasingly focus on the adoption of robotics on farms; these solutions are essentially suitable for all types of farm.

Our innovative solutions for feeding, milking, manure, and farm management aim to contribute to the improvement of animal welfare, lower the environmental impact of dairy farming and enhance farmer prosperity, and thus align well with our vision for the Farm of the Future.

Korstiaan Blokland

Director Innovations

‘As well as bringing new concepts to the market, innovation is about rethinking existing solutions. Our key focus is to offer the best solutions to make the lives of farmers easier. Our innovations can contribute to solving the environmental challenges we face in our sector.'

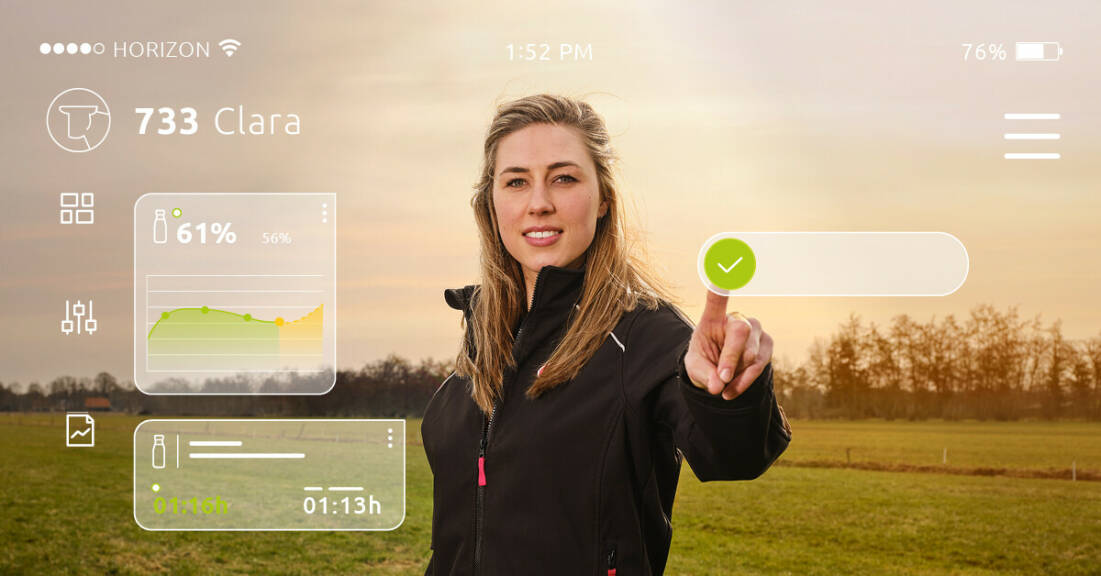

Digital / Horizon

In 2023, the migration of data management system T4C to Horizon was finalised. Over 20,000 customers worldwide use Horizon software daily. The system is always evolving, and it is Lely's commitment to continuously improve the platform. Using digital solutions makes it easier to monitor various aspects of farm management.

Manure / Collector & Sphere

In November 2023 the next generation Discovery Collector was launched, which has been improved in terms of battery life and charging speed. This model will be commercially available from Q2 2024.

Lely Sphere focuses on valorising manure to lower the environmental impact of dairy farming and to close the mineral cycle. In March, the circular barn system received an important Dutch certificate which states the system can realise an average of 77% nitrogen emission reduction in the barn. We have been running a Lely Sphere system in Denmark for two years now. The Danish government has made a subsidy available for reducing the environmental impact of dairy farming, which could have a positive impact on the Lely Sphere proposition in that region.

Feeding / Vector, Juno & Exos

A breakthrough for robotic feeding on XL farms. With the modified dosing system of the Vector, the farm can now fill the mixing and feeding robots faster to distribute the feed. The new Vector system improves feed efficiency and reduces feed cost with less residual feed.

A milestone for the Lely Juno, with the 15,000th feed pusher installed. The next generation Juno was also introduced; an updated model with improvements based on customer feedback.

The 2023 targets were met for Lely Exos. Fifteen Exos were active in Dutch fields, and together they collected more than 15 million kilos of fresh grass. By improving grass utilisation and lowering feed costs per kilo of milk produced by reducing conservation losses, Lely Exos can contribute to improving farmer prosperity.

Processing / Orbiter

The Lely Orbiter is an automatic on-farm dairy processor, which gives farmers the opportunity to process and market their own milk. In 2023, the 5th Orbiter was put into operation in the Netherlands. This next generation Lely Orbiter can also produce low fat yoghurt and milk for iced coffee.

Milking / Astronaut

We currently have around 50,000 Lely Astronaut robots active worldwide – and still we see the percentage of promoters increasing. Promoters are those customers who would recommend the purchase of an Astronaut to other farmers. During our annual customer satisfaction survey in November 2023, close to 70% of respondents were marked as a promoter. A better score than any we have ever had for previous models.

Driving innovation is not only about bringing new concepts to the market, it's also about improving existing solutions. Continuous improvement is one of the biggest pillars within our organisation. Every day, hundreds of employees work on improving existing solutions to better serve our customers’ needs.

Manure / Collector & Sphere

In November 2023 the next generation Discovery Collector was launched, which has been improved in terms of battery life and charging speed. This model will be commercially available from Q2 2024.

Lely Sphere focuses on valorising manure to lower the environmental impact of dairy farming and to close the mineral cycle. In March, the circular barn system received an important Dutch certificate which states the system can realise an average of 77% nitrogen emission reduction in the barn. We have been running a Lely Sphere system in Denmark for two years now. The Danish government has made a subsidy available for reducing the environmental impact of dairy farming, which could have a positive impact on the Lely Sphere proposition in that region.

Feeding / Vector, Juno & Exos

A breakthrough for robotic feeding on XL farms. With the modified dosing system of the Vector, the farm can now fill the mixing and feeding robots faster to distribute the feed. The new Vector system improves feed efficiency and reduces feed cost with less residual feed.

A milestone for the Lely Juno, with the 15,000th feed pusher installed. The next generation Juno was also introduced; an updated model with improvements based on customer feedback.

The 2023 targets were met for Lely Exos. Fifteen Exos were active in Dutch fields, and together they collected more than 15 million kilos of fresh grass. By improving grass utilisation and lowering feed costs per kilo of milk produced by reducing conservation losses, Lely Exos can contribute to improving farmer prosperity.

Processing / Orbiter

The Lely Orbiter is an automatic on-farm dairy processor, which gives farmers the opportunity to process and market their own milk. In 2023, the 5th Orbiter was put into operation in the Netherlands. This next generation Lely Orbiter can also produce low fat yoghurt and milk for iced coffee.

The coming year promises to be more challenging, due to some of the issues faced by farmers, such as low milk prices, high interest rates and political unrest. However, the long-term outlook for robotics and data management remains very bright.

Our focus for 2024 is the further development of competences in all regions, and the continuous improvement of our existing propositions to better serve our the needs of our customers. Alongside that, we will increasingly focus on the adoption of robotics on farms; these solutions are essentially suitable for all types of farm.

Our innovative solutions for feeding, milking, manure, and farm management aim to contribute to the improvement of animal welfare, lower the environmental impact of dairy farming and enhance farmer prosperity, and thus align well with our vision for the Farm of the Future.

Digital / Horizon

In 2023, the migration of data management system T4C to Horizon was finalised. Over 20,000 customers worldwide use Horizon software daily. The system is always evolving, and it is Lely's commitment to continuously improve the platform. Using digital solutions makes it easier to monitor various aspects of farm management.

Korstiaan Blokland

Director Innovations

‘As well as bringing new concepts to the market, innovation is about rethinking existing solutions. Our key focus is to offer the best solutions to make the lives of farmers easier. Our innovations can contribute to solving the environmental challenges we face in our sector.'

Milking / Astronaut

We currently have around 50,000 Lely Astronaut robots active worldwide – and still we see the percentage of promoters increasing. Promoters are those customers who would recommend the purchase of an Astronaut to other farmers. During our annual customer satisfaction survey in November 2023, close to 70% of respondents were marked as a promoter. A better score than any we have ever had for previous models.

Driving innovation is not only about bringing new concepts to the market, it's also about improving existing solutions. Continuous improvement is one of the biggest pillars within our organisation. Every day, hundreds of employees work on improving existing solutions to better serve our customers’ needs.