Develop a winning organisation

Back to

Strategy

Drive

innovation

Enhance customer

centricity

Create a successful

premium channel

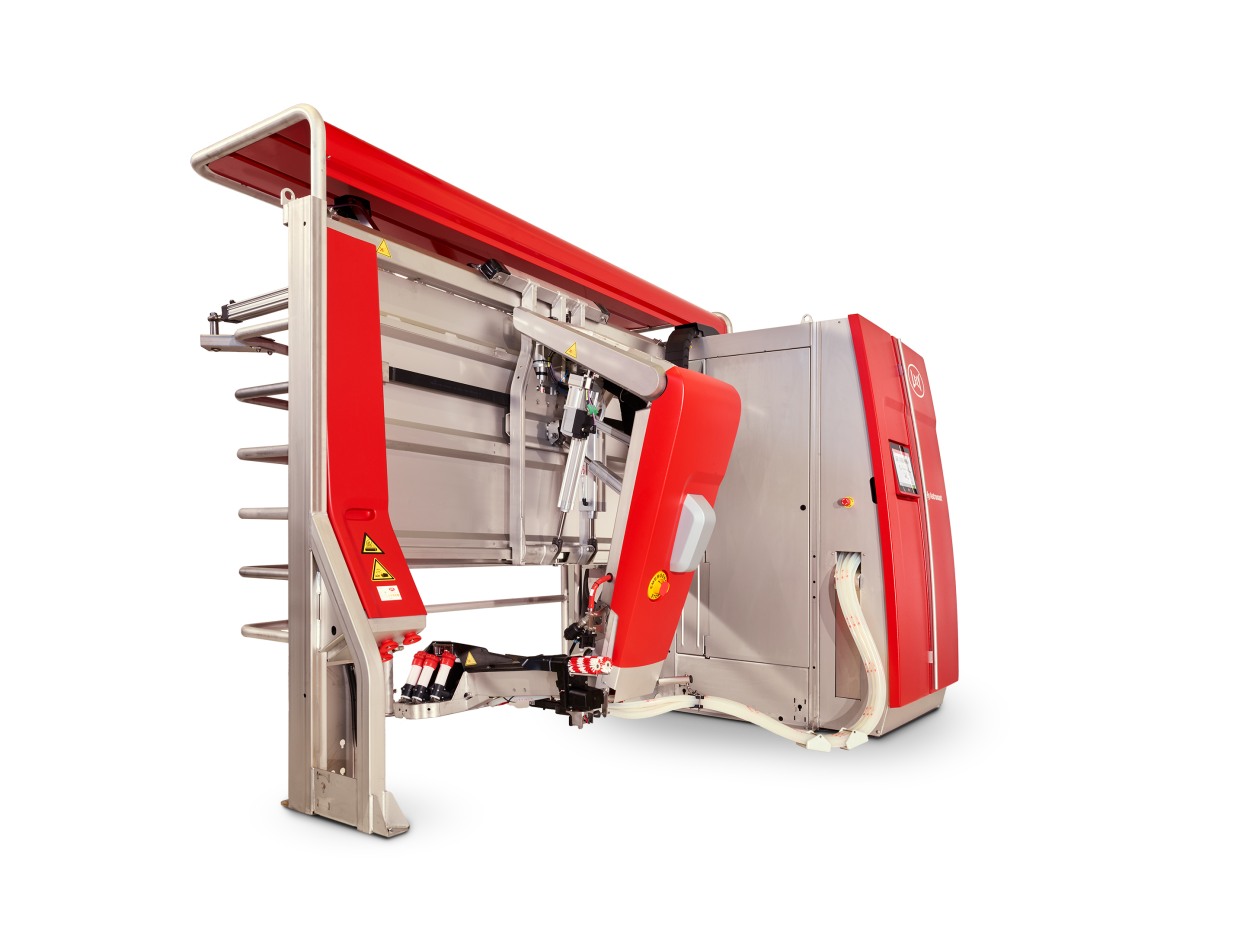

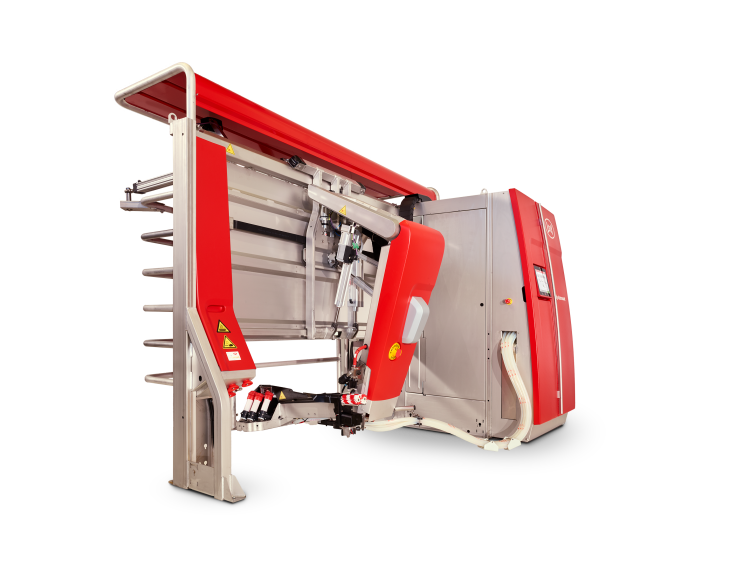

Our product development department works continuously to improve our products and make them more sustainable. In the last 20 years, the Astronaut has become 40% more energy efficient.*

* The presented consumption rates reflect best case performance and may not be relied upon. Actual consumption rates may vary depending on field and configuration circumstances. No rights can be derived from the information presented herein. E-mail us for testresults.

In 2021, the fourth MijnMelk maker, farmer Reijer, started producing milk on his own property with the Lely Orbiter. Dairy from the Orbiter is available in 1,000 supermarkets and through several online providers.

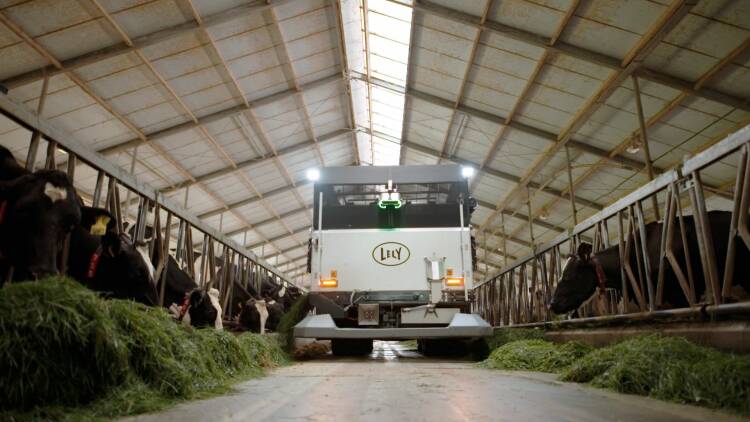

Following the widespread adoption of robotised milking, automatic feeding is on the rise as well. At the end of 2021, our orderbook for feeding products was already full for the coming year. At the same time, the shortage of components is still demanding our attention. We are dedicating capacity and effort to this issue to ensure we continue to provide the best possible service to our customers, as they should be able to expect from us. For example by offering quality alternatives for components that are no longer available.

Freddie Ruijs

Head of Value Team

Digital Farming

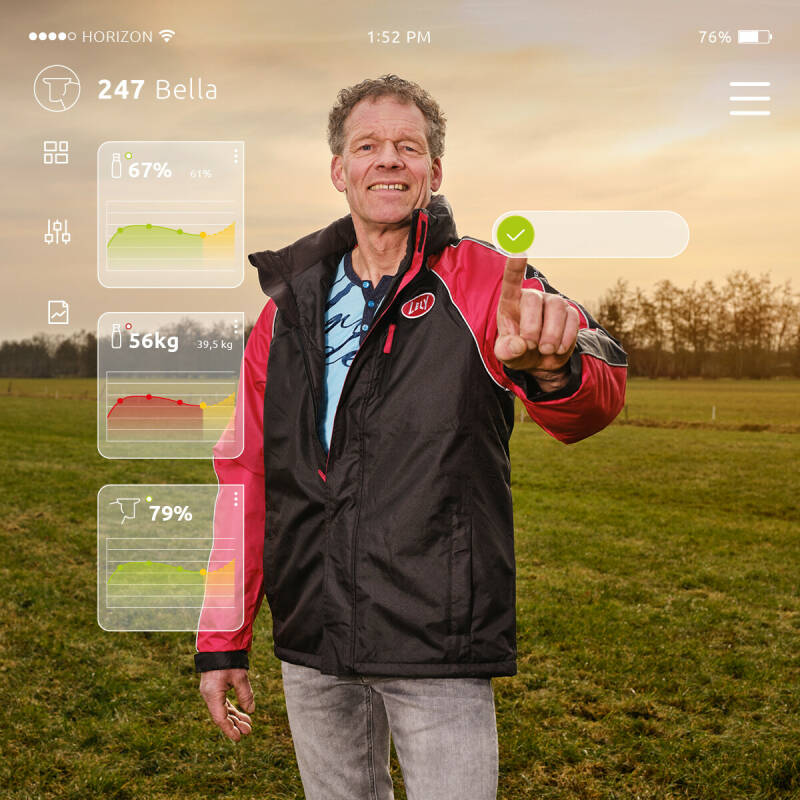

‘Using the farmers’ data, we can bring a lot of value to our customers. For example by automating complex cow-individual settings on the robots, such as brushing or concentrate feeding, which can change almost daily. Through data, we monitor the health of cows and warn a farmer when a cow needs attention, for instance when ketosis is suspected. A farmer can choose to share their data directly with their advisors, such as a veterinarian, for improved collaboration and better outcomes. All this to help a farmer optimise their business. To us, Horizon is not just a farm management system for our customers, but also a platform for industry partners to support us in our mission to help our farmers excel.’

Lely Orbiter produces ‘MijnMelk’

The Lely Orbiter is an advanced automatic on-farm dairy processer which is directly linked to the Lely Astronaut. The Orbiter allows farmers to distribute their dairy products straight from the farm to supermarkets and consumers, while increasing their profitability. In 2018, the first dairy farmer started producing milk on the farm. In 2021, the fourth Lely Orbiter was installed at a dairy farm in the Netherlands. Today, dairy from the Orbiter is sold in 1,000 supermarkets and several online channels.

MijnMelk – Premium milk from the Lely Orbiter

The MijnMelk brand – milk from the Lely Orbiter – has undergone enormous development this year. A fourth MijnMelk maker, farmer Reijer, started producing milk on his own property. In May, MijnMelk cream was introduced on the market. And as of December, farmer Guus is producing his own yoghurt with the Orbiter. With the newly developed Orbiter 2.0, every dairy farmer will be able to produce milk, cream and yoghurt. For 2022, we look forward to expanding abroad with the introduction of the Lely Orbiter in Belgium and Germany.

Exos

At the end of 2020, we proudly introduced the first ever concept for the autonomous harvesting and feeding of fresh grass: Lely Exos. A true revolution enabling dairy farmers to produce more milk per cow per day using grass from their own land, without extra labour.

In 2021, we further increased the number of testing machines driving around the field in preparation for the commercial launch in the coming years. This expansion helps us to gather more knowledge and experience and to further develop the product. The next step is to develop the service concept around the Exos. In addition, we are continuously researching how we can further optimise grassland management and at the same time improve the cows' rations so that the (quality of) production increases.

Sphere

In October 2021, our circular barn system Lely Sphere received recognition from the Dutch government as an important solution to the sector’s nitrogen challenges. This innovation reduces nitrogen emissions by more than 70%, converting the emissions into liquid circular fertiliser. During the next 12 months, we will undertake further efforts to bring this system to the market, and we call upon the Dutch government to support farmers in tackling the nitrogen challenges through innovation. We are now examining what the system needs in order to be introduced in other countries as well. In the meantime, we work on product development; for example, we are testing how we can make the system compatible with other floor types and how to best integrate the system in both existing barns and in newbuilds.

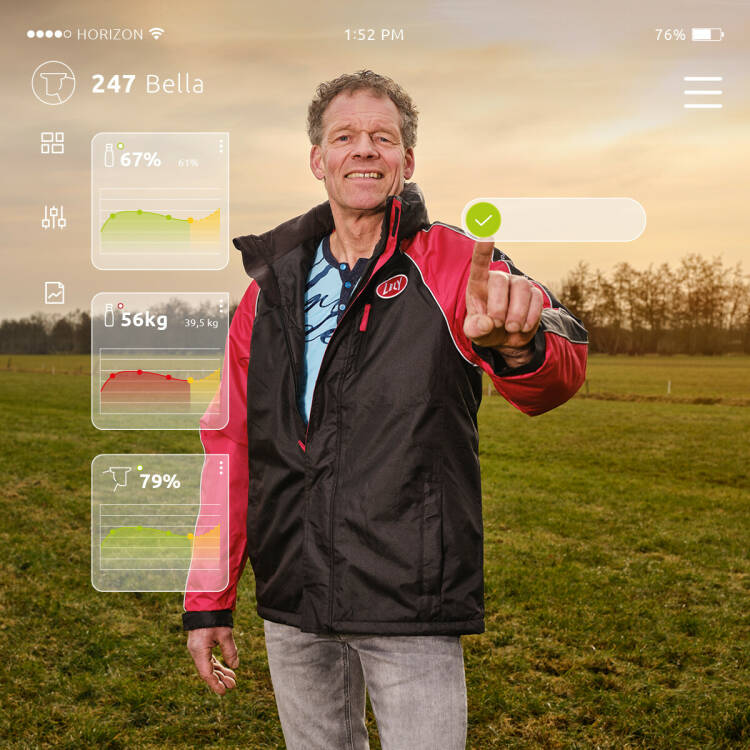

Horizon

This past year, we started the roll-out of Horizon, our new farm management system. Horizon monitors and collects data to help dairy farmers make better decisions and forecast and improve the performance of their cattle. Already 40% of our clients use Horizon. Early results indicate it is a valuable innovation with lots of potential. Lessons we learn from this implementation help us further improve the product. Our digital community, customer panels and clusters and centres provide us with valuable information to make adjustments on the job and constantly improve Horizon.

Our focus for 2022, besides expanding the roll-out to our entire customer base, is to guarantee a consistent quality to all farmers working with Horizon. Then we will focus on introducing new innovations for integration on the farm, for the exchange of data with farmers’ partners and to help our customers move towards data-driven decision-making.

Innovation is the answer to future challenges in the dairy sector. Labour shortages, growing world population, increasing focus on animal wellbeing and the environment. We believe automation is the answer and as a farming innovator, we do our best to support our dairy farmers to excel in sustainable dairy production.

* The presented consumption rates reflect best case performance and may not be relied upon. Actual consumption rates may vary depending on field and configuration circumstances. No rights can be derived from the information presented herein. E-mail us for testresults.

Our product development department works continuously to improve our products and make them more sustainable. In the last 20 years, the Astronaut has become 40% more energy efficient.*

In 2021, the fourth MijnMelk maker, farmer Reijer, started producing milk on his own property with the Lely Orbiter. Dairy from the Orbiter is available in 1,000 supermarkets and through several online providers.

Exos

At the end of 2020, we proudly introduced the first ever concept for the autonomous harvesting and feeding of fresh grass: Lely Exos. A true revolution enabling dairy farmers to produce more milk per cow per day using grass from their own land, without extra labour.

In 2021, we further increased the number of testing machines driving around the field in preparation for the commercial launch in the coming years. This expansion helps us to gather more knowledge and experience and to further develop the product. The next step is to develop the service concept around the Exos. In addition, we are continuously researching how we can further optimise grassland management and at the same time improve the cows' rations so that the (quality of) production increases.

Lely Orbiter produces ‘MijnMelk’

The Lely Orbiter is an advanced automatic on-farm dairy processer which is directly linked to the Lely Astronaut. The Orbiter allows farmers to distribute their dairy products straight from the farm to supermarkets and consumers, while increasing their profitability. In 2018, the first dairy farmer started producing milk on the farm. In 2021, the fourth Lely Orbiter was installed at a dairy farm in the Netherlands. Today, dairy from the Orbiter is sold in 1,000 supermarkets and several online channels.

MijnMelk – Premium milk from the Lely Orbiter

The MijnMelk brand – milk from the Lely Orbiter – has undergone enormous development this year. A fourth MijnMelk maker, farmer Reijer, started producing milk on his own property. In May, MijnMelk cream was introduced on the market. And as of December, farmer Guus is producing his own yoghurt with the Orbiter. With the newly developed Orbiter 2.0, every dairy farmer will be able to produce milk, cream and yoghurt. For 2022, we look forward to expanding abroad with the introduction of the Lely Orbiter in Belgium and Germany.

Sphere

In October 2021, our circular barn system Lely Sphere received recognition from the Dutch government as an important solution to the sector’s nitrogen challenges. This innovation reduces nitrogen emissions by more than 70%, converting the emissions into liquid circular fertiliser. During the next 12 months, we will undertake further efforts to bring this system to the market, and we call upon the Dutch government to support farmers in tackling the nitrogen challenges through innovation. We are now examining what the system needs in order to be introduced in other countries as well. In the meantime, we work on product development; for example, we are testing how we can make the system compatible with other floor types and how to best integrate the system in both existing barns and in newbuilds.

Following the widespread adoption of robotised milking, automatic feeding is on the rise as well. At the end of 2021, our orderbook for feeding products was already full for the coming year. At the same time, the shortage of components is still demanding our attention. We are dedicating capacity and effort to this issue to ensure we continue to provide the best possible service to our customers, as they should be able to expect from us. For example by offering quality alternatives for components that are no longer available.

Freddie Ruijs

Head of Value Team

Digital Farming

‘Using the farmers’ data, we can bring a lot of value to our customers. For example by automating complex cow-individual settings on the robots, such as brushing or concentrate feeding, which can change almost daily. Through data, we monitor the health of cows and warn a farmer when a cow needs attention, for instance when ketosis is suspected. A farmer can choose to share their data directly with their advisors, such as a veterinarian, for improved collaboration and better outcomes. All this to help a farmer optimise their business. To us, Horizon is not just a farm management system for our customers, but also a platform for industry partners to support us in our mission to help our farmers excel.’

Horizon

This past year, we started the roll-out of Horizon, our new farm management system. Horizon monitors and collects data to help dairy farmers make better decisions and forecast and improve the performance of their cattle. Already 40% of our clients use Horizon. Early results indicate it is a valuable innovation with lots of potential. Lessons we learn from this implementation help us further improve the product. Our digital community, customer panels and clusters and centres provide us with valuable information to make adjustments on the job and constantly improve Horizon.

Our focus for 2022, besides expanding the roll-out to our entire customer base, is to guarantee a consistent quality to all farmers working with Horizon. Then we will focus on introducing new innovations for integration on the farm, for the exchange of data with farmers’ partners and to help our customers move towards data-driven decision-making.

Innovation is the answer to future challenges in the dairy sector. Labour shortages, growing world population, increasing focus on animal wellbeing and the environment. We believe automation is the answer and as a farming innovator, we do our best to support our dairy farmers to excel in sustainable dairy production.